|

|

|

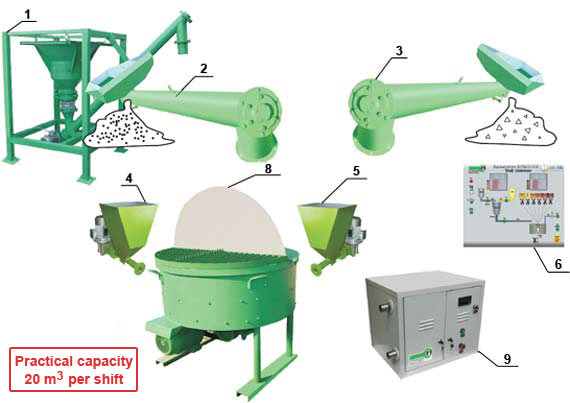

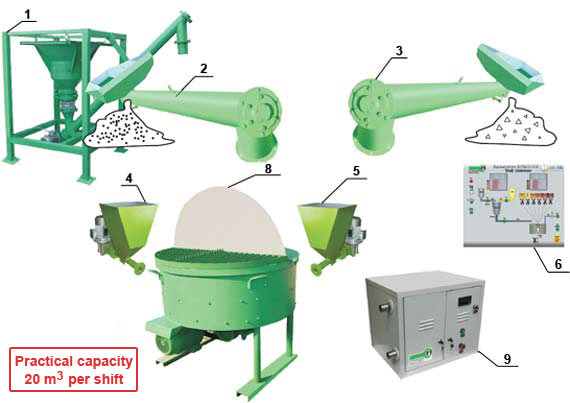

Automated concrete mix complex (ÀÌÊ) FORMBETON-LITEK

1 - Big bag unloader SR 500 with screw conveyor VK 114 (length 4 m), cement supply; 2 - screw conveyor VK 114 (length 4 m) with receiving hopper, sand supply; 3 - screw conveyor VK 114 (length 4 m) with receiving hopper, aggregate supply; 4 - agent batcher DMD 50Ò (pigment); 5 - agent batcher DMD 50Ò (agent); 6 - automated control system SAU 600 LOGIC; 7 - weighting hopper of inert and binding materials with knife shutter; 8 - concrete mixer SCAUT 300; 9 - automatic water pump batcher POTOK 8.150

The decorative finishing tile produced like natural materials is the most popular tile on the Russian market. To produce such expensive and qualitative product the multicomponent casting mix with increased content of agents and pigments is applied. The production of multicomponent mix requires the equipment that helps to batch accurately the applied materials, convey and mix components qualitatively. One of the most important reasons is the possibility to adjust equipment as quick as possible at introduction of new mix.

To produce highly-qualitative multicomponent mix applied at the production of decorative finishing concrete materials the machine building plant "Stroymechanika" offers the unique automated modular complex FORMBETON-LITEK, intended to produce qualitative multicomponent concrete mix, applied for further making of items by vibropressing and vibrocasting method. The standard complex is equipped with highly intellectual control system, that allows to produce up to fifty types of mix, in this case the system memorizes the proportions and they can changed by one bottom pressing.

Operation:

The main components (cement, sand and aggregate) are fed by turn with help of screw conveyors into the weighting hopper where are batched by weight and are thrown into the mixer SCAUT 300. The aggregates and pigments preloaded into the hoppers of agent batchers DMD 50T are batched by weight and enter the mixer's tank through batcher's screw. The quantity of batchers are determined according to content of prepared mix. The water is batched by water pump batcher POTOK 8.150. The concrete mixer SCAUT is equipped with set of injectors, mounted on the top of the mixer for uniform water distribution in the mixer at mix preparation. The components are mixed up to homogeneous state of set consistency. The ready mix is unloaded from the mixer through slide gate into the moulding device.

Content of the complex ÀÌÊ FORMBETON-LITEK (capacity of 20 m³ of ready mix per shift)

| 1 |

Big bag unlaoder SR 500 with screw conveyor VK 114 (length is 4 m), cement supply |

Overall dimensions 1560×1560×2200 mm,

ïîòðåáëÿåìàÿ ìîùíîñòü 1,5 kW |

1 set |

| 2 |

Screw conveyor VK 114 (4 m long) with feed hopper and built-in vibrating screen, sand supply |

Overall dimensions 8000×1020×595 mm,

power consumption 1,5 kW |

1 set |

| 3 |

Screw conveyor VK 114 (4 m long) with feed hopper, aggregate supply |

Overall dimensions 8000×1020×595 mm,

power consumption 1,5 kW |

1 set |

| 4 |

Agent batcher DMD 50Ò (pigment) |

Batching up to 50 kg (error ±0,5 kg),

overall dimensions 707×320×320 mm,

power consumption 0,75 kW |

1 set |

| 5 |

Agent batcher DMD 50Ò (agent) |

Batching up to 50 kg (error ±0,5 êã),

overall dimensions 707×320×320 mm,

power consumption 0,3 kW |

1 set |

| 6 |

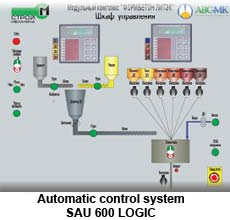

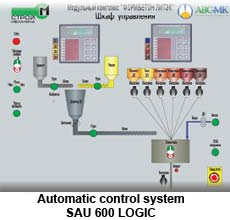

Automated control system SAU 600 LOGIC |

LG elements,

overall dimensions 600×360×600 mm |

1 set |

| 7 |

Weighting hopper of inert and binding materials with knife shutter |

Overall dimensions 2060×2060×3117 mm,

pneumatic drive of disk valve of "FESTO" production |

1 set |

| 8 |

Concrete mixer SCAUT 300 |

Overall dimensions 1400×1650×1200 mm,

power consumption 7,5 kW,

capacity up to 5 m³/h |

1 set |

| 9 |

Automated water pump batcher POTOK 8.150 |

Overall dimensions 600×430×350 mm,

power consumption 1,2 kW |

1 set |

Optional required equipment*

| ¹ |

Name |

Short technical data |

| 1 |

Silo 20 m³ |

Overall dimensions 560×565×880 mm |

| 2 |

Lifting device PU 03 |

Lifting height 2,4 m,

hoisting capacity 500 kg |

| 3 |

Vibrating table VIBROID 1000 |

Overall dimensions 1560×1560×2200 mm,

power consumption 3 kW |

| 4 |

Compressor Ê 11 |

Overall dimensions 100×47×80 mm,

power consumption 2,2 kW

capacity up to 0,16 m³/h |

* not a part of the complex and complex price

The intelligent control system SAU 600 LOGIC designed especially for such complexes by the well-known Russian company "AVS-MK", a partner of the machine building enterprise "Stroymechanika" controls the automated mixing complex FORMBETON-LITEK. The system SAU 600 LOGIC allows to adjust the complex both in manual and automatic operating mode. The control in automatic mode is made by pressing bottom "START". You can set up to 50 proportions of mixture from the control panel of SAU 600 LOGIC, and you can change proportions if it requires. The intelligent control system SAU 600 LOGIC designed especially for such complexes by the well-known Russian company "AVS-MK", a partner of the machine building enterprise "Stroymechanika" controls the automated mixing complex FORMBETON-LITEK. The system SAU 600 LOGIC allows to adjust the complex both in manual and automatic operating mode. The control in automatic mode is made by pressing bottom "START". You can set up to 50 proportions of mixture from the control panel of SAU 600 LOGIC, and you can change proportions if it requires.

The system SAU 600 LOGIC control the operation of:

- Big bag unloader SR 500 with screw conveyor VK 114 (cement supply);

- Screw conveyor ÂÊ 114 with feed hopper (inert aggregate supply);

- Weighting hopper for inert and binding materials (the batching of inert and binding materials entering the mixer by weight);

Agent batchers DMD 50Ò (the batching and supply of agents and pigments by weight); Agent batchers DMD 50Ò (the batching and supply of agents and pigments by weight);- Water pump batcher POTOK 8.150 (water batching to prepare concrete mix);

- Concrete mixer SCAUT 300 (preparation of smart multicomponent mix);

- Slide gate of the concrete mixer SACUT 300.

Competitive advantages of the complex AMK FORMBETON-LITEK: Competitive advantages of the complex AMK FORMBETON-LITEK:

- High automation level gives the possibility to operate in manual and automatic mode.

- Low price provides quick payback of the complex.

- Universality in raw mixes applied allows to work with different materials.

- High batching accuracy of used materials: 0,1-0,2% allows to low prime price.

- Low power consumption saves considerably the energy.

- High output provides the high productive efficiency.

- Autonomy of the complex gives possibility to operate with the complex just on building site.

- Short period of putting into operation allows to start as soon as possible the production and selling of ready articles.

Components of the complex ÀÌÊ FORMBETON-LITEK: Components of the complex ÀÌÊ FORMBETON-LITEK:

- Multipurpose reinforcement of Holland production;

- Componenst of pneumatic system

(Germany); (Germany);

- Control box components by

(South Korea) and (South Korea) and  (Germany); (Germany);

- Control bottoms by

production; production;

- Logical controllers of SAU 600 LOGIC by

(Russia) production; (Russia) production;

- Gear motor by CHIARAVALLI TRANSMISSIONI (Italy), MOTOVARIO (Italy);

- Load cells STC by Vishay Celtron production

. .

The application of the control system SAU 600 LOGIC as a part of the complex AMK FORMBETON-LITEK allows to reduce personnel working on the site that positively effects the payback period and the quality of the launched products.

Technical characteristics

| Overall dimensions (L×W×H), mm |

4300×4000×2500 |

| Total weight of the complex, kg |

1950 |

| Power, V |

380 |

| Power consumption, kW |

15 |

| Capacity, m³/shift |

20 |

| Compressed air consumption, l/min |

25 |

The complex AMK FORMBETON-LITEK is supplied tested and run.

The delivery set includes:

- operating manual for the equipment that is a part of the complex,

- operation manual for control system SAU 600 LOGIC,

- personnel training.

The complex can be supplied with:

- equipment for cement mechanical activation,

- contract supervision, montage,

- putting into operation,

- service maintenance (according to separate contract).

|

|

The intelligent control system SAU 600 LOGIC designed especially for such complexes by the well-known Russian company "AVS-MK", a partner of the machine building enterprise "Stroymechanika" controls the automated mixing complex FORMBETON-LITEK. The system SAU 600 LOGIC allows to adjust the complex both in manual and automatic operating mode. The control in automatic mode is made by pressing bottom "START". You can set up to 50 proportions of mixture from the control panel of SAU 600 LOGIC, and you can change proportions if it requires.

The intelligent control system SAU 600 LOGIC designed especially for such complexes by the well-known Russian company "AVS-MK", a partner of the machine building enterprise "Stroymechanika" controls the automated mixing complex FORMBETON-LITEK. The system SAU 600 LOGIC allows to adjust the complex both in manual and automatic operating mode. The control in automatic mode is made by pressing bottom "START". You can set up to 50 proportions of mixture from the control panel of SAU 600 LOGIC, and you can change proportions if it requires. Agent batchers DMD 50Ò (the batching and supply of agents and pigments by weight);

Agent batchers DMD 50Ò (the batching and supply of agents and pigments by weight); Competitive advantages of the complex AMK FORMBETON-LITEK:

Competitive advantages of the complex AMK FORMBETON-LITEK:

Components of the complex ÀÌÊ FORMBETON-LITEK:

Components of the complex ÀÌÊ FORMBETON-LITEK:

(Germany);

(Germany); (South Korea) and

(South Korea) and  (Germany);

(Germany); production;

production; (Russia) production;

(Russia) production; .

.