|

|

|

Supermobile concrete plant M0BILBET0N 15/750

This moment there are many offers regarding concrete plant delivery both stationary and mobile on the Russian construction market. Sometimes it is very difficult to make a choice of the right plant among all these proposals. Some clients who do not want to overpay, buy concrete plants made in China due to its low price and face a great deal of problems just after purchase. First of all it is a bad production quality, secondly, the defective control and weighting system is installed on these plants. The Turkish plants shipped to Russia, are not always satisfy a customer by performance quality as some elements of the plant are made in Russia in artisan undertaking and are not of good quality. Regarding automatic control systems all the concrete manufacturers apply the SIMENS controllers mainly, that are intended for operation and controlling of the automated complexes in the machinery construction.

The machine building enterprise "Stroymechanika" offers a super mobile concrete plant MOBILBETON 15/750, designed and manufactured by the enterprise. The mobile concrete plant MOBILBETON 15/750 is intended to store, convey batch of used materials and to prepare high-qualitative concrete mixes and mortars to use them in the buildings and edifices as well as at the production of construction materials. The machine building enterprise "Stroymechanika" offers a super mobile concrete plant MOBILBETON 15/750, designed and manufactured by the enterprise. The mobile concrete plant MOBILBETON 15/750 is intended to store, convey batch of used materials and to prepare high-qualitative concrete mixes and mortars to use them in the buildings and edifices as well as at the production of construction materials.

The application of mobile concrete plants "MOBILBETON" allows clients to widely realize different construction projects with complex design and long-distance placement from working infrastructure. So, the transport expenses to deliver concrete from stationary concrete plants to building sites are minimized. As a sequence it decrease the company's expenditures and enlarge the economic efficiency of performed work modernizes your production and open possibilities for further improvement.

Using mobile concrete plant of the plant "MOBILBETON" it is possible to produce:

- ready-mix concrete of density 2000 - 2500 kg/m³;

- polystyrene concrete mix of density 300 - 1600 kg/m³;

- special concretes from 300 to 2500 kg/m³.

One of the main feature of the mobile concrete plant "MOBILBETON" is that all units and assembles that take part in the preparation and production of concrete or mortar, are fixed on the trailer frame that is an integral part of eth concrete plant and represents the principal part of the mobile plant. Such disposition of units and assemblies allows to displace and slew mobile plant practically in any place. Due to simple modular design the mobile plant is assembled within some hours at minimal use of researches. Unlike stationary concrete plants the mobile plant does not require any complementary endorsements and documents registration at its displacement on the site. After the works have done, the concrete plant is easy to be transported to another site.

Composition of the mobile concrete plant MOBILBETON:

two-axle trailer ÏÒÑÒ-2×3,5 Ê, on which the following devices are mounted:

- forced action concrete mixer SCAUT 750Ì TURBO with operating volume 750 l (equipped with a gate with mechanical drive and steel cover with access to clean and inspection);

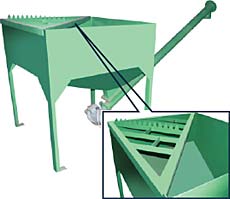

- two-section hopper for inert aggregates of total volume 6 m³;

- two belt conveyors to convey inert aggregates in mixer;

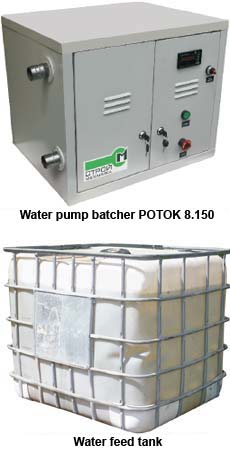

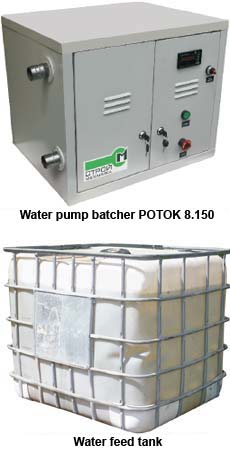

- tank 400 l and pimp water batcher POTOK 8.150;

- chemical agent pump batcher;

- high-pressure water pump;

- automated control system SAU MOBILBETON LOGIC.

Optional equipment:

Description of the mail modular of the mobile concrete plant MOBILBETON 15/750:

the mobile concrete plant MOBILBETON 15/750 is made based on certified trailer ÏÒÑÒ-2õ3,5Ê. The trailer has a welded frame, on which there are brackets to fix suspensions. Trailer hitch welded with loop is fixed on the frame by pins can be adjusted by height depending on towing coupler device of the truck. Nonseparable V-shaped design connecting frame beams with towing device serves to transfer towing force from truck to the trailer. There is a slewing coupling ring to connect with the truck. The truck suspension is independent with rubber - cord torsion bar on which UAZ wheel bosses are installed. The brake wheel mechanism is barrel-type, and unified with back brake mechanism UAZ-469. The trailer is equipped with back combinated lights, front fender lights and lights of illumination of registration plate that are installed on the outer support of the back of the platform. The back combined lights go on at the same time as car lights illuminate. The connection of the trailer with truck network is made through plug.

To install the mobile concrete "MOBILBETON" a horizontal solid area (for example, pavement plate) is required. The hydraulic drive of lifting supports (outriggers) allow to mount as quick as possible the principal module of the mobile concrete plant "MOBILBETON" without crane any other lifting device. To install the mobile concrete "MOBILBETON" a horizontal solid area (for example, pavement plate) is required. The hydraulic drive of lifting supports (outriggers) allow to mount as quick as possible the principal module of the mobile concrete plant "MOBILBETON" without crane any other lifting device.

The mobile concrete plant MOBILBETON 15/750 includes forced-action concrete mixer SCAUT 750 Ì TURBO. The hard mixes concrete mixer SCAUT 750 Ì TURBO is a machine with fixed bowl and rotary activator. The paddle rotary mixer activator with possibility to adjust working clearance of blades and paddles opening provides the qualitative mixing of mix components. The activator drive is in the bottom of the mixer that make easier loading and servicing. The mixer's activator is put into operation by the powerful planetary gear motor. The blades and paddles that have design allowing to adjust clearance between paddles and mixer's case. The armouring of the internal sheathing of the concrete mixer is replaceable, the mixer's bottom is protected with replaceable armour. The ready mix is unloaded from mixer's tank trough bottom gate that is installed in the bottom of the tank. The concrete mixer is installed on load sells, that allows to batch used materials just in the concrete mixer.

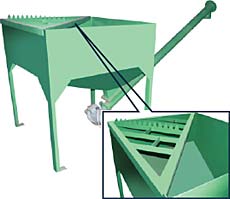

The storage of inert aggregates is made as a two-sectional bin. One section is used for crushed stone, the second for sand. The material is supplied in sections of feed by front wheel loader. In process of the materials expenditure the operator of the loader fills up the bin with required material. Under each sections of the bin a belt conveyor with which materials being in bins in certain sequence are supplied in the concrete mixer where they are mixed is installed. The storage of inert aggregates is made as a two-sectional bin. One section is used for crushed stone, the second for sand. The material is supplied in sections of feed by front wheel loader. In process of the materials expenditure the operator of the loader fills up the bin with required material. Under each sections of the bin a belt conveyor with which materials being in bins in certain sequence are supplied in the concrete mixer where they are mixed is installed.

Water to prepare concrete mix moves from water supply system in feed tank, then from feed tank enters the concrete mixer through pump batcher POTOK 8.150. Ordering heated feed tank, a heating element is mounted in the tank, and the tank is warmed.

Chemicals, intended to prepare concrete mix are pumped from plastic tank that is a part of the concrete plant, through pipeline of batching system of liquid agents and enter concrete mixer.

The mixing process takes 2-3 minutes depending on the proportions. The ready mix is unloaded through belt conveyor intended to convey ready mix as into the receptacle bin of the concrete pump as the truck mixer.

The technological process provides the clearing of concrete mixer from the stick concrete mix. The clearing of concrete mixer is made two times during a shift: the last batch before the lunch break and at the end of the shift the concrete mixer is loaded with crushed stones and water, their mixing is take place within 3-5 minutes then cement and sand are added. After the additional mixing of all components the ready mix is ready to be unloaded. After unloading the concrete mixer is washed out by water.

One of the obvious advantages of mobile concrete plants "MOBILBETON" is modular structure. Ordering plant a customer changes all the necessary modules depending on the materials to be produced.

List of modules of mobile concrete plant of "MOBILBETON" series

|

Module 1: Cement silo.

The volume of cement silo is determined not only by required capacity of the mobile concrete plant but schedule of cement supply. The cement loading into the vertical silo is made by pneumatic system of cement truck. The standard cement silo is equipped with hose filter, sensors of upper and lo cement level, aeration system, shaking device based on electromechanical vibrator. A screw conveyor is used to convey cement into concrete mixer.

| Designation |

Quantity |

Characteristics |

| Silo 12 m³ with screw conveyor VK 159 |

1 |

tank diameter 1,9 m;

tank height 5,93 m |

| Silo 20 m³ with screw conveyor VK 159 |

1 |

tank diameter 1,9 m;

tank height 8,7 m |

| Silo 30 m³ with screw conveyor VK 159 |

1 |

tank diameter 2,4 m;

tank height 8,9 m |

| Silo 40 m³ with screw conveyor VK 159 |

1 |

tank diameter 2,4 m;

tank height 11,1 m |

|

|

|

Module 2: Big bag (FIBCs) unloading system.

Big bag unloader SR 500 with screw conveyor VK 159 by the production of machine building enterprise "Stroymechanika" is intended to unload cement from FIBCs containers (like big bag). The bags with load capacity of 400-2000 kg of single or multipurpose application with valves of 110-140 mm are used for unloading. The operation of the unloader SR 500 with screw conveyor is controlled from automated control system chamber of the main module of the mobile concrete plant MOBILBETON 15/750.

|

|

|

Module 3: Unloader for valve bags.

The unloader of valve bags SR 50 with screw conveyor VK 159 by the production of machine building enterprise "Stroymechanika" is intended to unload cement from valve paper bags. The valve bags of load capacity more than 50 kg, of single or multipurpose application are used for unloading. The operation of unloader SR 50 with screw conveyor VK 159 is controlled from front panel of the automated control system of the principal module of the mobile concrete plant MOBILBETON 15/750.

|

|

|

Module 4: EPS batching

Volume granules batcher SDPO 1500.DZ by the production of machine building enterprise "Stroymechanika" is intended for volume batching of EPS granules (polyfoam) during the production of polystyrene concrete mix on the mobile concrete plant MOBILBETON 15/750. The operation of the volume batching system SDPO 1500.DZ is made from front panel of the automated control system chamber of the principal module of the mobile concrete plant MOBILBETON 15/750.

|

|

|

Module 5: Liquid components batching block (pump batchers of water and liquid agents of "POTOK" series)

Automatic pump batcher POTOK 8.150 by the production of machine building enterprise "Stroymechanika", being a part of standard arrangement of mobile concrete plant MOBILBETON 15/750 is intended for accurate batching and pressure supply of water through pipeline into concrete mixer. The automatic pump batcher POTOK 8.30, being a part of the standard mobile concrete plant MOBILBETON 15/750, is intended for accurate batching and pressure supply of mortar of chemical agent. The batchers of "POTOK" series operate in both automatic and manual modes. There are slots on the batchers body to connect pump batchers of "POTOK" series with external automated control system. The operation of pump batcher POTOK is controlled from front panel of automated control system chamber of the main module of the mobile concrete plant MOBILBETON 15/750.

|

|

|

Module 6: Liquid components preparation and batching plant

The preparation and batching plant for liquid components SJK 4000 by the production of machine building enterprise "Stroymechanika", is intended for batching of three liquid components from 1 to 999 liters at the same time by volume by continuous batching method. Applying the plant SJK 4000 as a part of the mobile concrete plant MOBILBETON 15/750 it is possible to prepare, batch accurately, and supply under pressure water and chemical agents required to make concrete mix with set technical characteristics. The operation of of the plant for volume batching of granules SDPO 1500. DZ is controlled from front panel of the automatic control system chamber of the plant SJK 4000 as well as from front panel of automated control system chamber of the main module of the mobile concrete plant MOBILBETON 15/750.

|

|

|

Module 7: Concrete mix conveying unit

Conveying unit of concrete mix SP LK is intended to convey ready concrete mix from concrete mixing plant of the mobile concrete plant MOBILBETON 15/750 to truck mixer, concrete pump both mobile an stationary, and also any other device intended for operation with concrete mix. At the same time the receiving bin of the unit should be under slide gate of the concrete mixer.

|

|

The large part of the complementary modules is supplied with mobile concrete plant "MOBILBETON" as an option. At the customer's option the client does not order the modules that will not be used; it helps to save money too.

The control of mobile control plant "MOBILBETON" is made applying intelligent system of automatic control system SAU MOBILBETON LOGIC, developed by famous Russian company "ÀVS-ÌÊ", a partner of eth machine building plant "Stroymechanika". The adjustment if made as manually as automatically.

System SAU MOBILBETON LOGIC controls the operation of: System SAU MOBILBETON LOGIC controls the operation of:

- Silo with screw conveyor VK 159 (cement conveying);

- Big bag (FIBCs containers) unlading system SR 500 with screw conveyor VK 159 (cement conveying) (option);

- Valve bags unloader SR with screw conveyor VK 159 (cement conveying) (option);

- Belt conveyors LK 300 with feed bin (ïinert aggregates conveying);

- Water pump batcher POTOK 8.150 (water batching by volume);

- Liquid agents pump batcher (chemicals batching by volume);

- Liquid components preparation and batching plant SJK 4000 (option);

- Volume EPS batcher DPO 1500.DZ (EPS batching by volume) (option);

- Forced action concrete mixer SCAUT 750 Ì TURBO (concrete mix preparation);

- Belt conveyor of "LK" series (unloading concrete mix from mixer);

- Air compressor;

- Water pump (washing of the complex).

The application of system SAU MOBILBETON LOGIC allows to reduce staff operating on the production site, that influence positively the payback speed of the unit and quality stability of produced equipment.

The last developments of the machine building company "Stroymechanika" are applied in the mobile concrete plant "MOBILBETON". They are forced action concrete mixer SCAUT 750 Ì TURBO, the liquid component preparation and batching plant SJK 4000.

The complex is made by applying the qualitative components:

(ASCO Joucomatic, Holland) locking-adjusting accessories); (ASCO Joucomatic, Holland) locking-adjusting accessories); (FESTO, Germany) components of pneumatic system; (FESTO, Germany) components of pneumatic system;- Control box components of

(LG, SouthKorea), (LG, SouthKorea),  (ABB, Germany); (ABB, Germany);

- Logical controllers of programmed control system of

(AVS-MK, Russia); (AVS-MK, Russia);

- Gear motors of

(CHIARAVALLI TRANSMISSIONI, Italy), MOTOVARIO (Italy). (CHIARAVALLI TRANSMISSIONI, Italy), MOTOVARIO (Italy).

Technical characteristics of mobile concrete plant MOBILBETON 15/750

| Capacity, m³/hour |

10-15 |

| Mixer |

forced-action |

| Power of mixer's drive, kW |

18 |

| Armoring |

yes |

| Bins, pc |

2 |

| Mixer's volume, l |

750 |

| Aggregates fraction quantity |

2 |

| Quantity of cement brands |

1 |

| Max aggregate size, mm |

up to 70 |

| Volume of one bin section, m³ |

3 |

| Automated control system |

PC automated control system |

| Aggregate and cement batching system |

weighting on load cells |

| Additives batching system |

volume |

| Drive power of water pump, kW |

5,5 |

| Quantity of pumps for chemicals |

1 |

| Control system |

AVS-MK |

| Quantity of formulas |

50 |

| Water heating |

yes |

Accuracy class of batcher

- by aggregates and cement, %

- by water, %

- by chemicals, % |

2

2

2 |

| Operating mode |

automatic/manual |

| Net weight (stationary performance/with trailer), kg |

3500/4500 |

| Overall dimensions (L×W×H), mm |

5200×2500×1470 |

| Height of mix unloading, mm |

800 |

| Height of bin boards, mm |

2400 |

| Supply voltage, V |

380 + 5% |

| Current frequency, Hz |

50 |

| Installed power, kW |

30 |

| Required inlet water pressure, Bar |

3 |

Technical characteristics of the trailer PTST-2×3,5 Ê

| Weight of load transported, kg |

3500 |

| Weight of loaded trailer, kg |

1000 |

| Total trailer's weight, kg |

4500 |

| Axle load, kg |

2215 |

| Trolley load, kg |

4430 |

| Drawbar load, kg |

70 |

| Maximal traverse speed of tractor-trailer, km/h |

40 |

| Overall dimensions (L×W×H), mm |

5200×2500×1470 |

| Wheel track, mm |

1700 |

| Road clearance, mm |

420 |

| Tyres, type, dimension |

road tyres 225/75 R16 |

| Inflation of pressure, atm |

2,5 |

| Brake |

mechanical drum, pneumohydraulic drive |

| Electrical equipment, V |

single-wire, 24 V |

| Suspension |

independent torsional |

Overall dimensions of mobile concrete plant MOBILBETON 15/750

Mobile concrete plants "MOBILBETON" are unique mobile plants on the Russian market guaranteeing stable quality and concrete mix content.

|

|

The machine building enterprise "Stroymechanika" offers a super mobile concrete plant MOBILBETON 15/750, designed and manufactured by the enterprise. The mobile concrete plant MOBILBETON 15/750 is intended to store, convey batch of used materials and to prepare high-qualitative concrete mixes and mortars to use them in the buildings and edifices as well as at the production of construction materials.

The machine building enterprise "Stroymechanika" offers a super mobile concrete plant MOBILBETON 15/750, designed and manufactured by the enterprise. The mobile concrete plant MOBILBETON 15/750 is intended to store, convey batch of used materials and to prepare high-qualitative concrete mixes and mortars to use them in the buildings and edifices as well as at the production of construction materials.

To install the mobile concrete "MOBILBETON" a horizontal solid area (for example, pavement plate) is required. The hydraulic drive of lifting supports (outriggers) allow to mount as quick as possible the principal module of the mobile concrete plant "MOBILBETON" without crane any other lifting device.

To install the mobile concrete "MOBILBETON" a horizontal solid area (for example, pavement plate) is required. The hydraulic drive of lifting supports (outriggers) allow to mount as quick as possible the principal module of the mobile concrete plant "MOBILBETON" without crane any other lifting device. The storage of inert aggregates is made as a two-sectional bin. One section is used for crushed stone, the second for sand. The material is supplied in sections of feed by front wheel loader. In process of the materials expenditure the operator of the loader fills up the bin with required material. Under each sections of the bin a belt conveyor with which materials being in bins in certain sequence are supplied in the concrete mixer where they are mixed is installed.

The storage of inert aggregates is made as a two-sectional bin. One section is used for crushed stone, the second for sand. The material is supplied in sections of feed by front wheel loader. In process of the materials expenditure the operator of the loader fills up the bin with required material. Under each sections of the bin a belt conveyor with which materials being in bins in certain sequence are supplied in the concrete mixer where they are mixed is installed.

System SAU MOBILBETON LOGIC controls the operation of:

System SAU MOBILBETON LOGIC controls the operation of:

(ASCO Joucomatic, Holland) locking-adjusting accessories);

(ASCO Joucomatic, Holland) locking-adjusting accessories); (FESTO, Germany) components of pneumatic system;

(FESTO, Germany) components of pneumatic system; (LG, SouthKorea),

(LG, SouthKorea),  (ABB, Germany);

(ABB, Germany); (AVS-MK, Russia);

(AVS-MK, Russia); (CHIARAVALLI TRANSMISSIONI, Italy), MOTOVARIO (Italy).

(CHIARAVALLI TRANSMISSIONI, Italy), MOTOVARIO (Italy).