|

|

StroyMechanika LTD |

||||||||||||

|

|

|||||||||||||

| Vibrating molds for well wall rings | Links | |||||||||||||

|

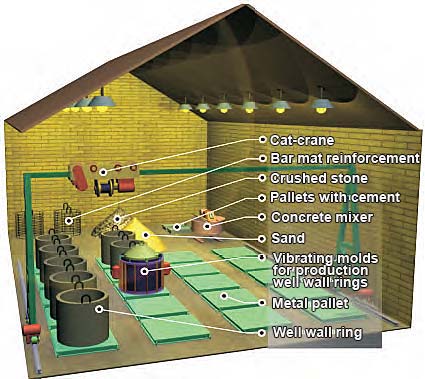

Vibrating molds for well wall rings of "VK" series

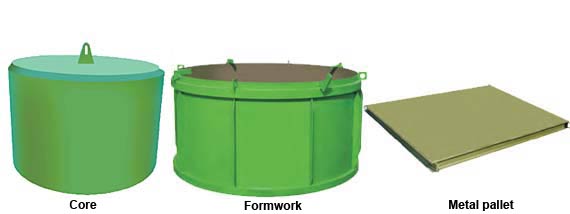

The formwork represents a hollow heavy steel cylinder equipped with strengthened shell ring, stiffeners and lifting eyes (4 eyes). On the formwork stops (4 stops) and vibrating units (based on the vibrator VI 99 B) are installed in the center of the mold to fix correctly the core. The core is a welded cylindrical hollow metal construction, its top part is a truncated cone-shaped with welded eye in the center, in the bottom a steel sheet ring of 80 mm by width is welded on. The vibrating mould is assembled as follows:

The vibrating molds is assembled and ready for operation. The vibrating mold is placed in shop of the wall rings production on pallets or plane concrete surface on which the ready products will be moulded and cured. To organize a production we recommend the following equipment:

At production the ready reinforced case according to GOST 23279-85 and concrete mix according to GOST 7473-94.

The applied vibrating devices developed on base of VI 99 B, are connected to the three-phase alternating-current network with 50 Hz frequency, and tension 380 V with solidly earthed neutral system through protective cutout device. The vibrator VI 99 B is a general electro-mechanic vibrator with circular vibration; is intended to activate vibration on the concrete mix compactors. The vibrator includes a three-phase cage induction motor and de-balancers installed on the rotor shaft ends. Overall dimensions

Technical characteristics

The technology of well ring production on the equipment of "Stroymechanika" Ltd

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| © 2004-2009 StroyMechanika LTD | Catalogue About us Contacts Dealers Foto & Video Site map |

The vibrating mold is a precast welded cylindrical metal construction. It consists of a casing, a core, and metal pallet.

The vibrating mold is a precast welded cylindrical metal construction. It consists of a casing, a core, and metal pallet.

The reinforced case (made in full compliance with technical documentation for wall rings) is installed in the vibrating mold assembled and ready for operation between external and internal moulding cylinder (between formwork and a core). The stops are fixed the core and the ready concrete mix (according to approved composition) is manually loaded. Then the vibrating packing is made in conformity with technological documentation (including formwork vibrators). After the concrete mix has been compacted, the vibrating mold is removed by lifting device and moved on the other pallet for further loading.

The reinforced case (made in full compliance with technical documentation for wall rings) is installed in the vibrating mold assembled and ready for operation between external and internal moulding cylinder (between formwork and a core). The stops are fixed the core and the ready concrete mix (according to approved composition) is manually loaded. Then the vibrating packing is made in conformity with technological documentation (including formwork vibrators). After the concrete mix has been compacted, the vibrating mold is removed by lifting device and moved on the other pallet for further loading.