|

|

StroyMechanika LTD |

||||||||||||

|

|

|||||||||||||

| Technology | Links | |||||||||||||

|

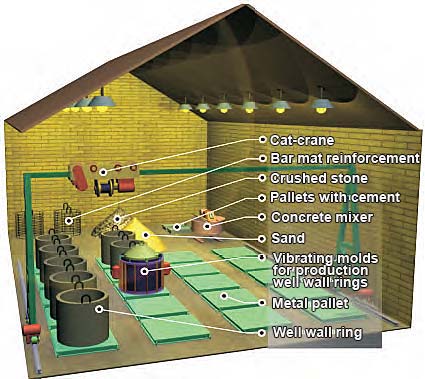

The technology of well ring production on the equipment of "Stroymechanika" LtdThe main merit of the present technology is easy in operation, that helps to receive well rings with ideal front service. To organize the production it needs the following equipment: concrete mixer "SCAUT", , equipped with electric or manual drive of the lifting device. The ready reinforcing frame is used during the production (you can manufacture it yourselves). The smart surface where the ready articles will be moulded and stacked is required for the process. Example of the shop organization to produce well rings

Operation with vibrating mold to produce well ringsThe ready concrete mix is fed between internal and external forming cylinders by shovels. Then the vibrating compaction is made (1-3 minutes), after that the unit is taken off by lifting device and moved on eth smart surface to be loaded further. Incoming components:

Proportion for 1 m³ of ready concrete (standard ratio):

Attention!!! Rise density in 10 kg/cm?, increasing cement content in the mix in 10-15%, if is required!!! Proportions of mortars

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ¹ | Designation | Components | Concrete density, kg/m³ | Brand of concrete and corpulent stone, kg/m³ | Brand of corpulent stone, kg/m³ |

|---|---|---|---|---|---|

| 1 | Cement, kg Quartz sand m³ (kg) Water, l |

240 1,15 (1950) 90...130 |

2200 | 130 | 80 |

| 2 | Cement, kg Quartz sand, m³ (kg) Crushed stone, m³ (kg) Water, l |

200 0,54 (920) 0,65 (980) 90...130 |

2100 | 150 | 90 |

| 3 | Cement, kg Îòñåâ, ì³ (kg) Crushed stone, m³ (kg) Water, l |

200 0,3 (450) 0,8 (1200) 90...130 |

1900 | 130 | 75 |

| 4 | Cement, kg Siftings, m³ (kg) Water, l |

200 1,1 (1650) 90...130 |

1900 | 85 | 50 |

| 5 | Cement, kg Quartz sand, m³ (kg) Granite crushed stone, m³ (kg) Water, l |

200 0,54 (920) 0,65 (1100) 90...130 |

2300 | 170 | 100 |

Quality certificate for reinforced well rings

Qualitative characteristics

| ¹ | Characteristics | Units of measurement | According to GOST 66701-84 | Fact |

|---|---|---|---|---|

| 1 | Concrete class (brand) of products by compressive resistance | kg/cm² | B15 M200 | B20 M300 |

| 2 | Concrete class by frost resistance | - | F50 | F100 |

| 3 | Water absorption | % | 4 | |

| 4 | Reinforcement | screen Âð-1 d 4-5 step 200 | screen Âð-1 d 4-5 step 200 | |

| 5 | Deviation from geometric parameters: length, width, thickness | mm | ±5 | ±5 |

Note:

It is admitted on the product surface:

- cissings by diameter no less than 10 mm and by depth no less than 5 mm;

- local builtup and cavities of 5 mm by height and by depth;

- concrete chips by depth no more than 8 mm and total length no more than 200 mm;

- shrinkage and other surface technological cracks, those length should not exceed 0,1 mm.

Conclusion of the technical control department: it meets fully the requirements of GOST 66701-84.

Reinforcement of well ring

If you have no possibility to use ready reinforcing nets during the making of well ring, you can manufacture them yourselves (according to GOST 66701-84).

| About us | ||||||||||||||||||||||||

|

|

||||||||||||||||||||||||

| Services | ||||||||||||||||||||||||

|

Consultations and services in the building materials production Development of technical specifications and technological schedules Contract supervision of the equipment |

||||||||||||||||||||||||

| Our dealers | ||||||||||||||||||||||||

|

||||||||||||||||||||||||

| © 2004-2009 StroyMechanika LTD | Catalogue About us Contacts Dealers Foto & Video Site map |