|

|

StroyMechanika LTD |

||||||||||||

|

|

|||||||||||||

| PRACTIKA 1000 | Links | |||||||||||||

|

Moulding plant PRACTIKA 1000

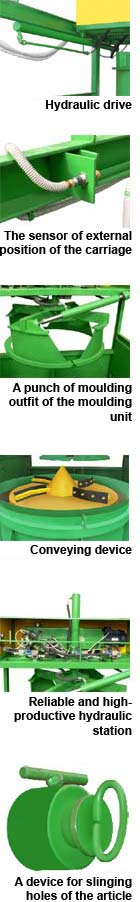

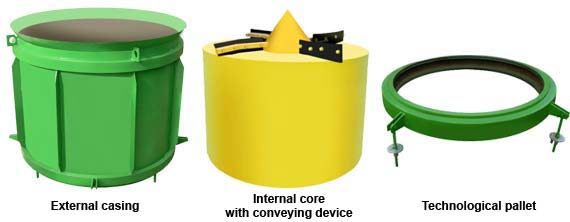

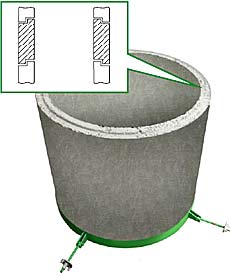

Every day in the building market of Russia hundreds concrete well rings of the various sizes are sold. Manufacturers of given production face a problem of the choice of the accessible and qualitative, reliable and high-efficiency equipment. Unfortunately, for today the equipment satisfying completely the requirements set forth above, does not practically meet in the market, as consequence, high labour coefficient of manufacturing and poor quality of launched well rings are. However the technical decisions, allowing to make high-quality competitive production in the conditions of the small and average enterprises of the building industry, exist! The machine building enterprise "Stroymechanika", being one of the leading manufacturers of eth construction equipment in the central part of Russia, offers a moulding plant PRACTIKA 1000. The moulding plant PRACTIKA 1000 is the best variant of quality-price ratio, applying the moulding unit the problems of manufacturing of qualitative wall well rings are solved. Having the compact dimensions, reasonable power consumption, low noise level, as well as low price, this unit it is capable to make about 40 concrete rings per shift. The moulding complex gives the possibility to receive products in height of 900 mm and diameter up to 1 metre. The capacity of the unit is 40 concrete rings in a shift. The molding complex includes a foundation, the moulding table with the metal core is mounted on the foundation. On vertical racks of the foundation the guides for moving of the movable carriage are established, on the basis of the carriage oil station and puncheon hydraulic drive are is established. The moulding set of moulding complex consists of a formwork, a core and the metal pallet. The formwork has the form of the hollow sheet steel cylinder, equipped with reinforcing ribs. In the bottom part of the formwork, four stops are mounted to fix it correctly on the special metal pallet. The core is made as a welded cylindrical hollow cylinder which top part has a basis on which the conveying device is mounted, from the interior of the core the vibrating devices are installed (based on vibrator VI 99). The forming complex is assembled in shop on the manufacturing of wall rings on the plane concrete platform, anchor the moulding unit according to the documentation on the equipment. For the manufacturing of wall concrete rings by means of the moulding plant PRACTIKA 1000 it is necessary to have the following equipment: concrete mixer SCAUT 300 or similar, the lifting device PU 03 by the production of the machine-building enterprise "Stroymechanika", equipped with the lifting mechanism with the electric or manual drive. At the manufacturing the ready reinforced frame in accordance with GOST 23279-85 and a concrete mix in accordance with GOST 7473-94 are used. The ready concrete mix enters the foundation of the feed device located in the top part of the core of moulding set, and is loaded into a clearance between an external formwork and the internal core by means of blades of the conveying device which automates the filling with mix. At filling the mould the reinforcing rings or the reinforced framework made in accordance with GOST 23279-85 are laid. The moulding of the ring up to the finished size and demanded compaction occurs under the effect of vibration and a punch clip on the product upper edge. The punch plate has a ledge which together with the figured pallet established in the bottom part of the product allows to receive on a product interlock elements. The core vibration gives the possibility to reach the uniform compaction of walls of the product on height, and the rotary movement of the interlock gives the possibility to receive the plane interlocking profile. In the assembled and ready for operation moulding fixture the reinforced frame is established made in accordance with engineering specifications on wall rings, between the external and internal form-building cylinder (between the formwork and the core). The feed device is switched on, and the concrete mix is loaded manually with shovels or by means of the loading device (belt conveyor) prepared according to the approved formula. Then the vibrating compaction is made in conformity with the technological documentation (core vibrators including).

After the moulding has been made, the mobile carriage of the moulding complex of the device moves to the back of the moulding unit. The ready product together with a formwork and the pallet attached to it removed from the core and is transported to the zone of the technological curing by means of the overhead runway beam or lifting device PU 03 by the production of machine-building enterprise "Stroymechanika". Having opened the form clamps, the article is liberated together with the pallet, and the formwork comes back to the moulding section. The moulding complex PRACTIKA 1000 do not require a qualified staff and safety in work. The application of the parts of well-known Italian manufacturers allows to make the qualitative and reliable hydraulic drives applied in unit, that is excellent for work of the unit in turn. The moulding complex is intended for operation indoor or out-of-doors under half-house at minimal operational ambiance temperature +5°Ñ.

Technical characteristics

The set of supply includes: mouldng unit PRACTIKA 1000, technological moulding pallet, operating manual. The machine building enterprise "Stroymechanika" equips the production of wall rings of series "SCAUT" (SCAUT 80, SCAUT 200, SCAUT 300) and lifting device PU 03, equipped with electromechanical lifting device upon customers desire.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| © 2004-2009 StroyMechanika LTD | Catalogue About us Contacts Dealers Foto & Video Site map |

The special features of the moulding complex for formation of well rings PRACTIKA 1000:

The special features of the moulding complex for formation of well rings PRACTIKA 1000:

,

,  .

.