|

|

StroyMechanika LTD |

||||||||||||

|

|

|||||||||||||

| Vibropress VP 7Ì ILYA MUROMETS | Links | |||||||||||||

|

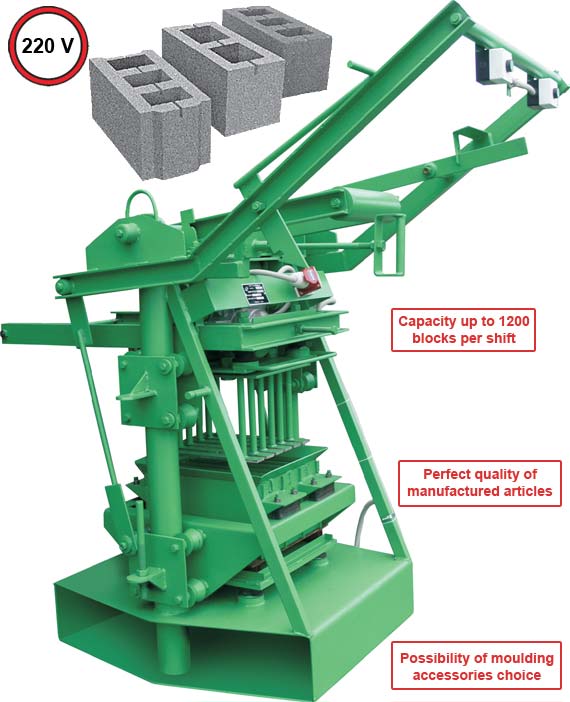

Electro-mechanical vibropress VP 7Ì ILYA MUROMETS

The application of the vibropress VP 7M allows as quick as possible to organize the production of qualitative construction material, both building blocks and partition blocks, paving tiles and other products in full conformity with State Spec. GOST 6133 - 99, on the special areas with minimal initial production costs. Using the vibropress VP 7M the making of blocks on light-weight aggregates such as polystyrene or expanded clay became possible. The products are molded by the volume vibropressing method. The average productivity per shift of the vibropress VP-7Ì is 13 m³ (about 1000 pieces) of qualitative building stones fully corresponding to requirements of GOST 6133-99. The new model of the vibropress differs:

At development of vibropress VP 7Ì the special attention was given to operating easiness with the unit, to reduction of time of the production cycle and decrease the cost price of launched production. Thus, the customer can make the replaceable technological pallets used for products moulding himself according to delivered drawings. As a material of pallets the metal, wood, plastic, and other sheet materials can be used. The application of replaceable pallets allows to reduce considerably the required production areas, having applied various stacking methods of finished articles. The vibropress is equipped with protective cutout device, the operation voltage is 220 V, that allows to organize the production of qualitative building materials on the sites where there is no connection with three-phase power network of 380 V. The presence of 2 electromechanical vibrators installed on the vibrating table and on the top sealant, allows to receive stones with excellent operational characteristics. The vibropress is simple in operation, and expenses on its maintenance service are reduces as much as possible due to absence of expensive in service and difficult in adjustment hydraulic drives. The vibropress is easy in operation and it is served by two operators. The vibropress is equipped with:

At moulding of masonry units and other building materials on the vibropress VP 7Ì the sand, fuel slags (from burning of coal, peat, anthracite), crushed stone from a volcanic tufa (a limy tufa) and shell limestone, brick ballast (a crushing waste), ashes, a limestone sawing waste, a marble aggregate, and light aggregates, for example: expanded clay, polystyrene, or organic aggregates: wood sawdust and other waste can be applied as an aggregate. Applying the vibropress VP 7Ì the modern building materials such as masonry units with the application of polystyrene granules as a aggregate upon the technology StroyPolyStyrene, and also masonry units on the basis of wood sawdust upon technology Dobrolit are received. The distinctive features of the vibropress are:

To start production it is necessary to buy a vibropress VP 7Ì, concrete mixer SCAUT 200Ì TURBO or SCAUT 300Ì TURBO, some pallets. To start the equipment into operation is possible next day without complementary preparation. The vibropress VP 7Ì ensures high accuracy of masonry units making with stable characteristics of density, durability, frost resistance, water absorption. The products made on vibropresses of series VP by the production of machine-building enterprise "Stroymechanika" are similar to the products made on the expensive equipment by quality and appearance. Technical characteristics

* the delivery in three tones container is possible

Please, specify the power tension ordering the equipment: The moulding accessories for the vibropress are manufactured according to your order. Building blocks, received on the vibropress VP 7Ì ILYA MUROMETS Paving slab, received on the vibrppress VP 7Ì ILYA MUROMETS Ceiling blocks, received on the vibrppress VP 7Ì ILYA MUROMETS Concrete mixer SCAUT

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| © 2004-2009 StroyMechanika LTD | Catalogue About us Contacts Dealers Foto & Video Site map |

The vibropress VP 7Ì (improved model) manufactured by the machine building enterprise "Stroymechanika" is intended for large range of construction equipment due to the application of replaceable dies made according to the required product.

The vibropress VP 7Ì (improved model) manufactured by the machine building enterprise "Stroymechanika" is intended for large range of construction equipment due to the application of replaceable dies made according to the required product. Attention! To male moulding concrete mix it is recommended the application of stiff concrete mix mixers of force.

Attention! To male moulding concrete mix it is recommended the application of stiff concrete mix mixers of force.